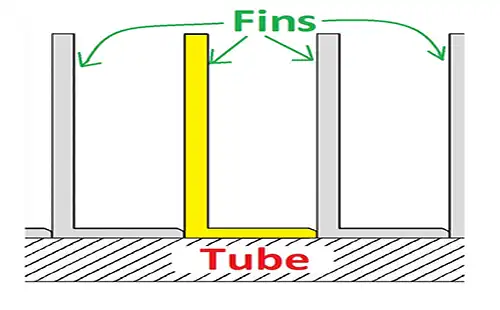

Wrap-on fins, also known as L-foot fins or tension-wound fins, are a type of metal fins used to enhance the heat transfer surface area in heat exchangers. These fins are typically made of aluminum, copper, or steel and are helically wrapped around hollow tubes.

Wrap-on Fin Manufacturing Process

The wrap-on finning process is a simple and cost-effective method for increasing heat transfer surface area. It is widely used in various applications, including oil and gas refineries, chemical and petrochemical industries, natural gas processing, and steelmaking.

- Fin Strip Preparation: A thin strip of heat-conductive metal, usually aluminum, is passed through a special machine.

- Foot Formation: The machine creates a small edge on one side of the strip, known as the “foot.” Two common foot types are:

- L-foot: A simple 90-degree bend at the fin root.

- T-foot: Two 90-degree bends and a 180-degree bend at the fin root, providing more stability than the L-foot.

- Helical Winding: The strip is tightly wound around the tube. The fin strip tension is maintained by crimping or securing it with a ring at both ends of the tube. L-foot finned tubes are suitable for low-temperature applications.

Advantages of Wrap-on Finning

- Low-Temperature Applications: Ideal for heat exchangers operating at low temperatures.

- Cost-Effective Method: The most economical finning method.

- Easy Fin Replacement: Damaged fins can be easily replaced if bent or torn.

- No Spiral Groove Required: Unlike other methods, no spiral groove is needed on the base tube.

- Suitable for Thin-Walled Tubes: Fins can be attached to thin-walled tubes, especially beneficial when using expensive alloys for the base tube.

- Corrosion and Thermal Stress Resistance at Low Temperatures: Tubes are resistant to atmospheric corrosion and thermal stress up to 130°C.

Disadvantages of Wrap-on Finning

- Low Mechanical Strength of Fins: Wrap-on fins have lower mechanical strength.

- Susceptibility to Tearing and Bending: Prone to tearing and bending.

- Limited Cleaning with Steam or High-Pressure Water: Steam or high-pressure water is not suitable for cleaning these tubes and can damage the fins.

- Formation of Finless Areas: The helical winding creates finless areas on the tube, exposing them to environmental corrosion. Galvanic corrosion can also occur at the fin-to-tube joint.

- Requirement for Smooth and Straight Tubes: The base tube must be smooth and straight for proper finning.

- Securing Fin Ends: Fins must be secured at both ends to prevent detachment.

Applications of Wrap-on Fins

Wrap-on fins, also known as L-foot fins or tension-wound fins, are widely used in various industries due to their simplicity, cost-effectiveness, and efficient heat transfer capabilities. Their primary applications include:

Oil and Gas Refineries

Wrap-on fins are commonly employed in low-temperature heat exchanger coolers within oil refineries due to their simplicity and cost-efficiency.

Chemical and Petrochemical Industries

These fins are utilized in heat exchangers operating at low temperatures across various industries, including chemical and petrochemical production.

Natural Gas Processing

Wrap-on fins are preferred in gas cooling heat exchangers due to their elimination of the need for spiral grooves and their lightweight construction.

Steelmaking Industries

Wrap-on fins find applications in water cooling systems within the steelmaking industry.

Key Considerations

- Fin Selection: The choice of fin type for a heat exchanger depends on various factors, including the fluid type, operating temperature, working pressure, space constraints, and budget.

- Manufacturer Guidelines: Before using wrap-on fins, carefully review and follow the manufacturer’s instructions to ensure proper installation and operation.

- Fin Damage: Promptly replace any damaged fins to maintain heat transfer efficiency and prevent further damage to the heat exchanger.

Conclusion

Wrap-on fins offer a cost-effective and efficient solution for heat transfer enhancement in low-temperature applications. Their simplicity and ease of manufacturing make them a popular choice in various industries. However, their lower mechanical strength and susceptibility to damage require careful handling and maintenance.

Leave a Reply