Extruded fin tubes represent a revolutionary approach to heat transfer technology. These tubes are manufactured using an innovative process that integrates fins directly onto the tube surface, enhancing heat transfer efficiency and providing a robust and durable solution for various applications.

Manufacturing Process Extruded fin tubes

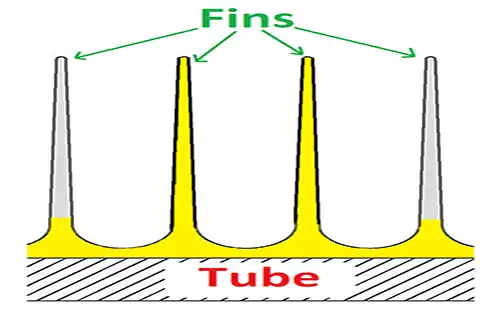

The production of extruded finned tubes involves a unique process that seamlessly integrates fins into the tube structure. This process begins with an aluminum tube and a cylindrical aluminum sleeve that houses the fluid-carrying tube.

Combining Tube and Sleeve

The tube and sleeve are placed into a machine equipped with rotating dies.

High-Pressure Extrusion

Under intense pressure (around 1200 psi), the dies force the aluminum sleeve to extrude outwards, forming helical fins around the tube.

Fin Formation

This extrusion process increases the fin height to the desired level while leaving a substantial thickness of aluminum around the fluid tube, completely encasing it.

Continuous Fin Production

The extrusion is carried out using a three-roller die extrusion machine, producing a continuous finned tube.

Cold Working and Bonding

The high pressure applied during this cold-working process ensures an exceptional bond between the tube and fins, resulting in exceptional heat transfer efficiency and significantly enhanced mechanical strength of the fins.

Applications

Extruded finned tubes have gained widespread recognition in various industrial applications due to their superior performance and durability. Their primary areas of use include:

- Air Coolers: These tubes are extensively employed in air coolers for effective heat dissipation.

- Dryers: Their high heat transfer efficiency makes them ideal for use in dryers across various industries.

- Radiators: Extruded finned tubes are prevalent in radiators for efficient heat exchange.

- Industrial Applications: These tubes are widely used in power plants, chemical industries, steel mills, and chillers due to their robust construction and high heat transfer capabilities.

Advantages of Extruded Finned Tubes

Extruded finned tubes offer a compelling range of benefits that make them a preferred choice for demanding heat transfer applications:

- Cold Extrusion Manufacturing: The cold extrusion process imparts exceptional strength and durability to the tubes.

- Superior Fin-to-Tube Bond: The strong bond between the fins and the tube ensures efficient heat transfer.

- Exceptional Heat Transfer Efficiency: The optimized fin design maximizes heat exchange.

- High Mechanical Strength: Extruded finned tubes can withstand high pressures and stresses.

- Corrosion Protection: The complete encasement of the tube body by fins provides corrosion protection (except for the bare ends).

- Wide Operating Temperature Range: These tubes can handle temperatures up to 300°C.

In conclusion, extruded finned tubes stand out as a superior heat transfer solution, offering a combination of high efficiency, durability, and versatility that makes them a valuable asset in a wide range of industrial applications.

Leave a Reply