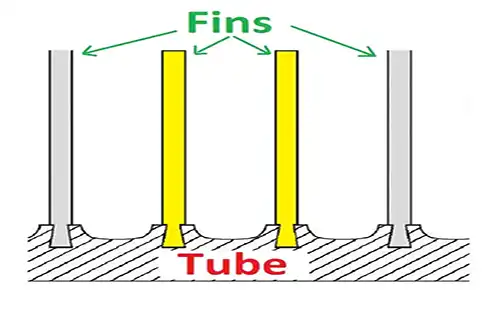

Embedded finned tubes, also known as G-type finned tubes or press-fit finned tubes, offer a robust and corrosion-resistant solution for heat transfer applications. These tubes are manufactured by embedding fins into a helical groove machined on the outer surface of the base tube, creating a secure and durable bond that enhances heat transfer efficiency.

Manufacturing Process

The production of embedded finned tubes involves a unique process that integrates fins into the tube structure:

- Groove Machining: A continuous helical groove is created on the outer surface of the base tube using a machining process, such as milling or grooving. The depth of the groove typically ranges from 0.2 to 0.3 millimeters (0.008 to 0.012 inches).

- Fin Insertion: A thin aluminum fin strip is inserted into the helical groove, ensuring a tight fit and minimizing gaps.

- Groove Closure: The edges of the groove adjacent to the fin are pressed or rolled onto the fin root using specialized tooling, completely enclosing the fin within the groove.

- Bond Validation: The strength of the fin-to-tube bond is verified through rigorous testing, often involving pull tests to ensure the fin can withstand the required load without detaching.

Finned tubes, also known as heat transfer tubes with fins, are a type of heat exchanger that enhances heat transfer efficiency by increasing the contact surface area between the fluid and the surrounding environment. They consist of hollow tubes with fins attached to their outer surface, typically made from aluminum, copper, or steel. Finned tubes offer several advantages, making them a popular choice in various industrial applications.

Advantages of Finned Tubes

- High Fin Stability and Excellent Heat Transfer: Finned tubes provide exceptional heat transfer due to the stable bond between the fins and the tube, ensuring efficient heat dissipation from the fluid to the surrounding environment.

- High Operating Temperature: Finned tubes can withstand high operating temperatures, typically up to 450°C (842°F), making them suitable for demanding applications involving hot fluids.

- Redundancy and Reliability: Even if a portion of the fin is damaged, the complete connection along the tube length prevents the entire fin from detaching, maintaining some level of heat transfer capability.

- Cost-Effectiveness: Finned tubes offer a cost-effective solution for heat transfer compared to other methods, particularly in applications where space is limited.

Disadvantages of Finned Tubes

- Lower Mechanical Strength: Finned tubes have lower mechanical strength compared to plain tubes, making them more susceptible to damage from external impacts or excessive pressure.

- Difficult Transportation: The presence of fins can make finned tubes more challenging to transport and handle, requiring extra care to prevent damage.

- Vulnerability to Cleaning Methods: High-pressure steam or water cleaning methods may damage the fins, necessitating careful selection of cleaning techniques.

- Potential for Corrosion: The helical arrangement of fins creates areas without fins, exposing these areas to corrosion from environmental factors and galvanic corrosion at the fin-to-tube joint.

- Strict Tube Requirements: Manufacturing high-quality finned tubes requires a smooth and defect-free base tube, increasing production costs.

- Limited Repair Options: In case of fin damage, repairing or replacing the fins can be difficult, and in some cases, the entire tube may need to be replaced.

- Fin Securing: Securing the fins at both ends is crucial to prevent their detachment, adding to the manufacturing complexity.

Applications of Embedded Finned Tubes

Oil and Gas Refineries

Finned tubes are extensively used in oil and gas refineries for heat exchange processes, such as crude oil preheating and product cooling.

Petrochemical and Chemical Industries

Their high heat transfer efficiency makes them ideal for various heat exchange applications in the petrochemical and chemical industries.

Natural Gas Treatment

Finned tubes play a vital role in natural gas treatment processes, including dehydration, sweetening, and liquefaction.

Steel Industry

Finned tubes are widely employed in the steel industry for cooling processes, such as quenching and annealing.

In conclusion, finned tubes offer a versatile and effective solution for heat transfer applications, particularly in industries where high heat transfer efficiency, corrosion resistance, and durability are critical. However, their lower mechanical strength, susceptibility to cleaning methods, and potential for corrosion in certain areas need to be carefully considered during design and operation.

Leave a Reply