I have a comprehensive understanding of the properties of refractory materials. Refractories, also known as refractory ceramics or firebricks, are a group of non-metallic inorganic materials with high resistance to heat and high temperatures. They are widely used in the construction of furnaces, crucibles, reactors, and other industrial equipment that are exposed to extreme heat.

Due to their unique properties, refractories play a crucial role in various industries, particularly in steel, cement, glass, petrochemical, and metallurgical sectors.

Key Properties of Refractory Materials

High-Temperature Resistance

The most critical property of refractories is their ability to withstand exceptionally high temperatures without melting or deforming. This characteristic stems from the strong atomic structure and chemical bonds of these materials, imparting them with resilience and stability against heat.

Chemical Corrosion Resistance

Refractories must be resistant to corrosive chemicals, such as molten metals, acids, and alkalis, to prevent erosion and degradation in industrial environments where these substances are present.

Thermal Shock Resistance

Thermal shock refers to sudden temperature changes that can cause cracking and fracturing of materials. Refractories must withstand this phenomenon to avoid damage during rapid heating and cooling cycles.

Low Thermal Conductivity

Low thermal conductivity implies slow heat transfer through the material. This property is essential in refractories to minimize heat loss and maintain high temperatures within furnaces and industrial equipment.

Mechanical Strength

Refractories must possess adequate mechanical strength to bear their own weight and pressure, as well as additional loads like equipment and molten materials.

Density

Low density in refractories signifies lighter weight for a given volume. This characteristic facilitates easier transportation and installation, while also reducing the burden on supporting structures.

Types of Refractory Materials

Refractories are classified into various categories based on criteria such as chemical composition, application, and production method. Some of the most common types of refractories include:

Silicate Refractories

Composed of silicates, such as clay, quartz, and feldspar, these refractories are widely used due to their high heat resistance and cost-effectiveness.

Alumina Refractories

Formed from aluminum oxide (alumina), these refractories exhibit exceptional resistance to heat, chemical corrosion, and thermal shock, making them suitable for steel, cement, and petrochemical industries.

Magnesia Refractories

Comprising magnesium oxide (magnesia), these refractories are particularly resistant to basic slags and are employed in glassmaking, cement production, and metallurgical processes.

Zirconia Refractories

Based on zirconium oxide (zirconia), these refractories offer exceptional chemical stability, high melting points, and excellent thermal shock resistance, catering to demanding applications in the glass, ceramic, and aerospace industries.

Basic Refractories

Composed of oxides of calcium, magnesium, or chromium, these refractories are resistant to basic slags and are used in steelmaking, cement kilns, and non-ferrous metal refining.

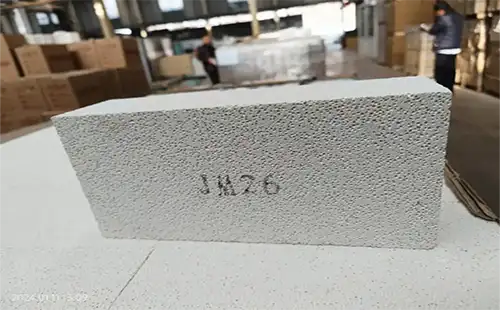

Insulating Refractories

Designed to minimize heat loss, these refractories are characterized by low thermal conductivity and are employed in furnace linings, boilers, and other applications where heat conservation is crucial.

The selection of the appropriate refractory material depends on the specific requirements of the application, considering factors like temperature range, chemical environment, mechanical loads, and desired thermal conductivity.

Applications of Refractory Materials

As mentioned earlier, refractory materials have a wide range of applications across various industries. Some of the most prominent uses of these materials include:

1. Furnace Construction

Refractories are essential in constructing the bodies and inner linings of furnaces, crucibles, and reactors in industries like steel, cement, glass, petrochemical, and metallurgical sectors.

2. Coating of Pipes and Ducts

Refractory materials are employed to coat pipes and ducts that transport molten materials or hot gases, preventing corrosion and erosion.

3. Manufacturing Refractory Components

Refractories are used to fabricate refractory components such as firebricks, refractory blocks, refractory pipes, and refractory fibers, which find applications in various industries.

4. Thermal Insulation

Certain refractory materials, such as mineral wool and glass wool, serve as thermal insulation in buildings and industrial equipment.

Selecting Refractory Materials

Choosing the appropriate type of refractory material for each application depends on various factors, including working temperature, type of molten material or gas, chemical environment, mechanical stresses, and economic considerations. This selection plays a crucial role in enhancing equipment lifespan, reducing maintenance costs, and improving the efficiency of industrial processes.

Conclusion

Refractory materials are indispensable in various industries and play a critical role in industrial processes. Given the diversity of refractory types and applications, careful selection and implementation of these materials are essential for ensuring optimal performance, safety, and cost-effectiveness in industrial operations.

Leave a Reply