This company proudly offers a wide range of insulating bricks, as a leading manufacturer, to various industries, including oil and gas refineries, petrochemical plants, and related industries.

The company’s insulating bricks are used in numerous furnaces and thermal engineering projects across Iran.

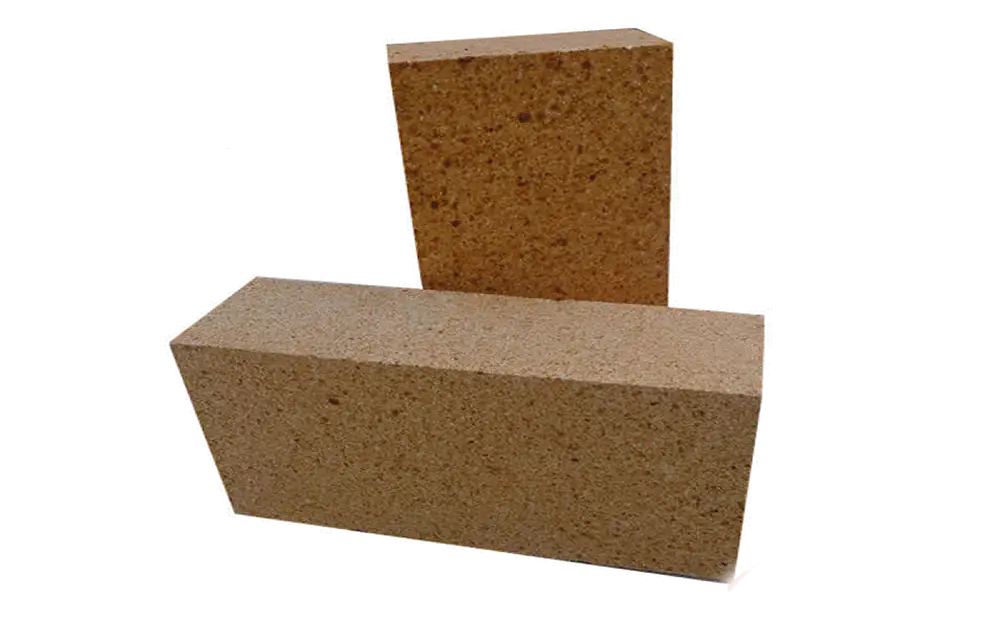

Competitive Advantages of Insulating Bricks

Superior Quality

The company’s insulating bricks are manufactured from the finest refractory raw materials, including high-quality alumina and premium organic fillers. This results in the delivery of unique properties such as high strength, excellent thermal insulation, low heat storage, low thermal shrinkage, and very low iron and impurity content.

Energy Efficiency

Owing to their exceptional thermal insulation properties, the company’s insulating bricks significantly reduce energy consumption, leading to substantial cost savings.

Versatile Applications

These bricks are suitable for a wide range of applications, including:

- Hot face lining of furnaces

- Primary process kilns

- Forge furnaces

- Blast furnaces

- Chimneys

- Scrubbers

- Reactor chambers

- Ceramic kilns

- Laboratory furnaces

- Fireplaces

Benefits of Utilizing insulating Bricks

- Extended Service Life: Refractory bricks are renowned for their exceptional durability, offering years of continuous service in extreme conditions. Their ability to withstand harsh environments minimizes the need for frequent replacements, reducing maintenance costs and downtime.

- Reduced Energy Consumption: The exceptional thermal insulation properties of refractory bricks translate into reduced heat loss, leading to significant energy savings. This translates into lower operating costs and a smaller environmental footprint for industrial operations.

- Enhanced Process Efficiency: Refractory bricks contribute to efficient thermal processes by maintaining consistent temperatures and minimizing heat loss. This ensures optimal heat transfer, leading to improved product quality and reduced production time.

- Elevated Safety Standards: The chemical resistance and structural integrity of refractory bricks enhance safety in hazardous environments. Their ability to withstand harsh conditions prevents accidents and protects personnel from potential harm.

- Environmentally Friendly: Refractory bricks are often manufactured from recycled materials and can be reused or recycled at the end of their service life. This commitment to sustainability minimizes their environmental impact and promotes eco-conscious industrial practices.

Technical specifications of

insulating bricks

Services

- Expert consultation in selecting the most suitable insulating brick for each application

- Design, installation, and commissioning of various heavy-duty furnaces

- Comprehensive solutions for reducing energy consumption and cost savings

.For more information and free consultation, contact our experienced experts

Leave a Reply