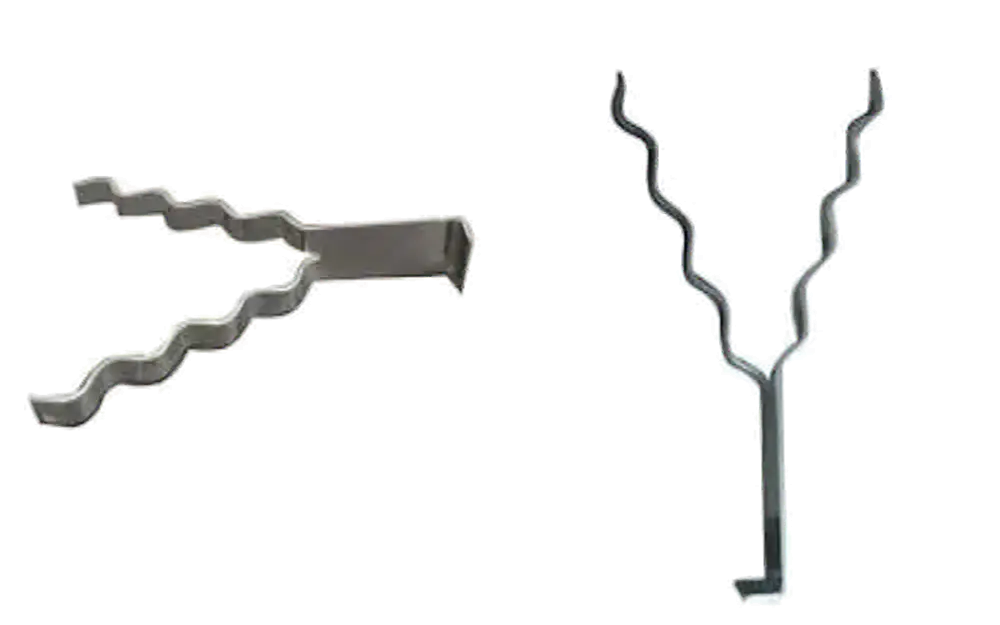

Refractory steel anchors also known as refractory anchors, are a type of fastener used to secure and connect refractory materials in high-temperature environments. These anchors are made from special alloy steels that can withstand extreme heat, stress, and corrosion.

We are a leading manufacturer of a wide range of refractory steel anchors in various shapes for diverse applications.

Materials:

Our refractory anchors are made from high-grade stainless and refractory steels in various grades, including:

- 1.4845

- 1.4541

- 1.4401

- 1.4301

- Inconel

- And more

Features of Refractory Steel Anchors

- High resistance: to chemical environments and oxidation

- Dimensional stability: no shape changes under mechanical load

- Thermal stability: withstands high temperatures

Applications of Refractory Steel Anchors

Refractory anchors are used in various thermal applications across different industries, including:

Cement Industry

- Rotary kilns: to secure refractory bricks and inner lining against high thermal and mechanical stresses

- Chimneys: to connect chimneys to structures and prevent vibration and detachment

- Cement silos: to anchor equipment and prevent movement due to vibration and oscillation

- Other thermal equipment: such as mills, preheaters, and clinker coolers

Steel Industry

- Melting furnaces: to secure refractory bricks and inner lining against high heat and mechanical stresses

- Flues: to connect flues to structures and prevent vibration and detachment

- Boilers: to anchor equipment and prevent movement due to vibration and oscillation

- Other thermal equipment: such as heating furnaces, annealing furnaces, and hot rolling mills

Oil and Gas Industry

- Refineries: to secure refractory bricks and inner lining of reactors, furnaces, and heat exchangers against high heat and mechanical stresses

- Cracking furnaces: to anchor equipment and prevent movement due to vibration and oscillation

- Heat exchangers: to connect exchangers to structures and prevent vibration and detachment

- Other thermal equipment: such as pipelines, storage tanks, and burners

Petrochemical Industry

- Steam boilers: to secure refractory bricks and inner lining against high heat and mechanical stresses

- Reactors: to anchor equipment and prevent movement due to vibration and oscillation

- Pipelines: to connect pipelines to structures and prevent vibration and detachment

Other Industries

- Power plants: to secure refractory bricks and inner lining of boilers, turbines, and heat exchangers against high heat and mechanical stresses

- Waste incineration plants: to anchor equipment and prevent movement due to vibration and oscillation

- Metal melting furnaces: to connect furnaces to structures and prevent vibration and detachment

- Other high-temperature industrial installations: such as glass, ceramic, and mineral industries

Technical Specifications

For the latest product specifications, please refer to the attached file at the bottom of this page.

This file provides detailed technical information for various anchor types,

including 1. 4845, 1. 4401, 1. 4301 and Inconel 601.

Inconel & Super Alloys

Benefits of Refractory Steel Anchors

- · High quality: Use of premium raw materials and precise manufacturing processes

- · Variety: Offering a wide range of anchors in different grades and shapes

- · Competitive pricing: Providing products at competitive prices

- · After-sales service: Offering technical consultation and support to customers

For more information or to place an order, please contact us.

Leave a Reply