Ceramic refractory coatings are a diverse group of materials that offer a range of unique properties and applications. These coatings are composed of inorganic ceramic materials, often combined with binders and additives, that provide exceptional thermal resistance, chemical stability, and abrasion resistance. They are widely used in various industries, including furnaces, kilns, power plants, and chemical processing facilities, to protect and extend the lifespan of critical components.

Types of Ceramic Refractory

Coatings

Ceramic Adhesive

Composition: A blend of ceramic materials, organic and inorganic binders, and a water base

Applications:

- Bonding ceramic pieces together or to metal substrates.

- Adhering boards, blankets, lightweight and heavy bricks to each other or to metal structures.

- Serving as a refractory mortar with high initial strength for joining refractories of varying densities.

- Repairing cracks in precision casting molds and rubber foam molds.

Refractory Rating: 1550°C (2822°F)

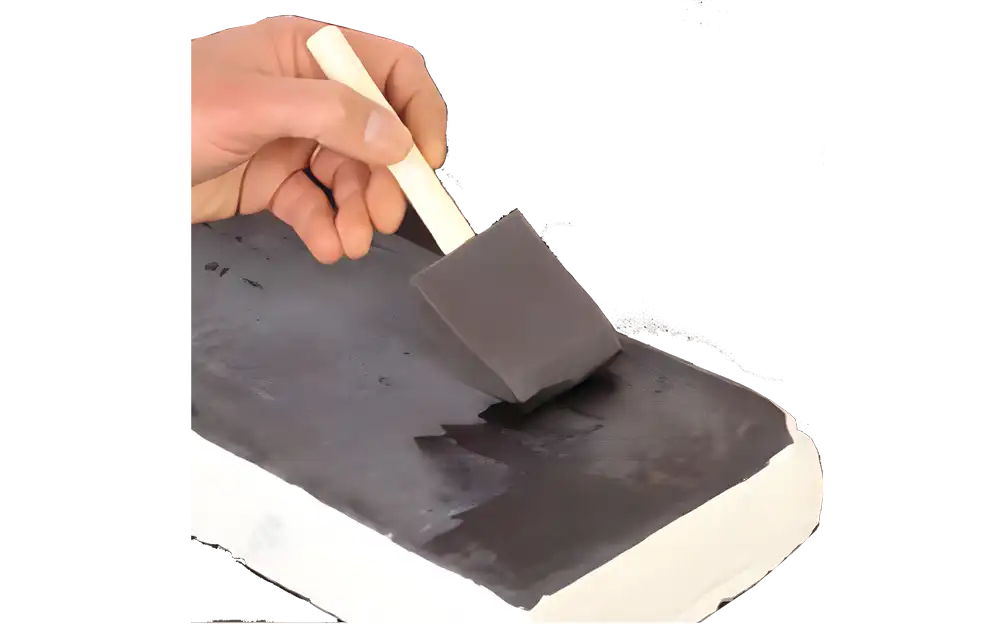

Fast-Setting Refractory Concrete

Characteristics: A specialized refractory concrete designed for rapid setting

:Advantages

- Cures and hardens within hours to days, compared to weeks for conventional refractory concretes.

- Eliminates the need for special curing procedures.

- Sets gradually 15 minutes after application and achieves initial set within an hour.

- Available in a faster-setting formula for repairs in ceilings or other areas requiring quick set times.

Setting Behavior:

- Relatively insensitive to heating rate during the curing process.

- Recommended heating rate not to exceed 250°C per hour.

Customization:

Customizable formulations with varying setting times available upon request.

Applications:

- Emergency repairs: Ideal for situations requiring rapid repair of refractory equipment or surfaces.

- Furnace and chimney lining: Suitable for lining furnaces, chimneys, and other high-temperature surfaces.

- Thin refractory layers: Applicable for creating thin refractory layers on various substrates.

- Casting refractory shapes: Suitable for casting refractory shapes with complex geometries and unique designs.

Other Ceramic Refractory Coatings

In addition to ceramic adhesive and fast-setting refractory concrete, a wide range of other ceramic refractory coatings exist, each with its specific properties and applications.

Conclusion

Ceramic refractory coatings offer a versatile and effective solution for protecting and enhancing the performance of components in high-temperature environments. Their exceptional thermal resistance, chemical stability, and abrasion resistance make them indispensable in various industries, ensuring the longevity and efficiency of critical equipment.

Leave a Reply