Rockwool insulation, also known as mineral wool insulation, is a type of thermal insulation composed of mineral fibers, primarily derived from basalt rock. This versatile insulation material offers a range of benefits that make it a valuable asset for various applications in construction and industry.

Advantages of Rockwool Insulation

This rockwool stands out due to its exceptional properties, providing numerous advantages:

- Fire Resistance: Rockwool insulation is non-combustible and does not emit toxic smoke in case of fire, making it an ideal choice for buildings and industrial facilities.

- Sound Insulation: The porous structure of rockwool effectively absorbs sound waves, reducing noise transmission and creating a quieter environment.

- Energy Efficiency: This thermal insulation rockwool significantly reduces heat transfer, minimizing energy consumption and lowering heating and cooling costs.

- Environmental Friendliness: This type of rockwool is made from natural materials and is recyclable. It also contains no harmful substances, posing no threat to human health or the environment.

Types of Rockwool Insulation

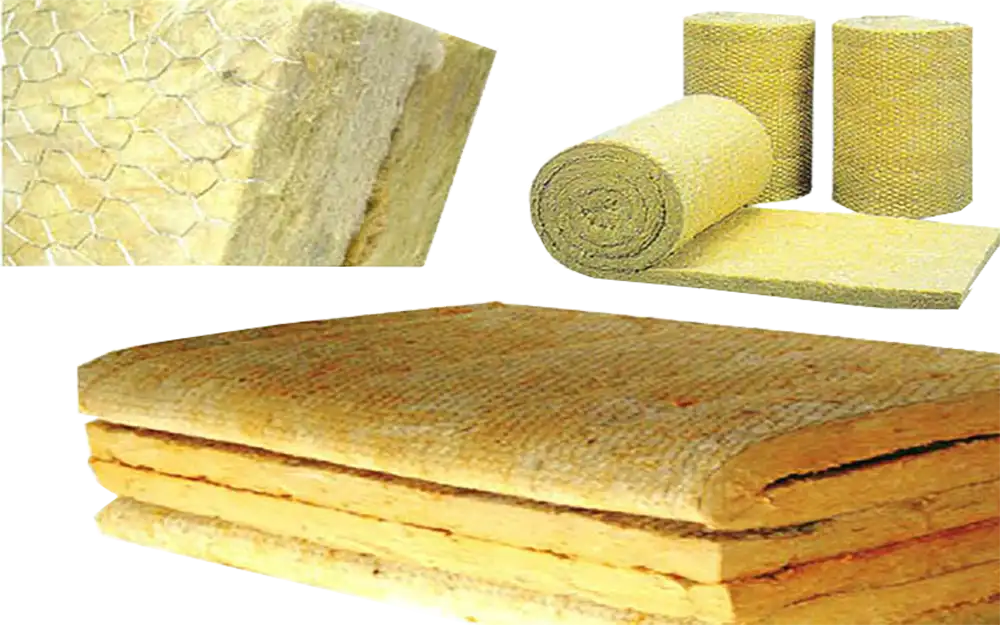

Rockwool insulation comes in various forms to suit specific applications:

Isoblankets

These are available in rolls or boards and are ideal for insulating flat and curved surfaces, large-diameter pipes, furnaces, boilers, tall chimneys, turbine exhausts, and greenhouses.

Isopipes

Supplied in tubular form, isopipes are designed for insulating pipes carrying hot or cold fluids.

Phenopanels

These compressed boards are used for insulating walls, ceilings, and floors.

Phenofelts

Produced in roll form, phenofelts are suitable for insulating ducts, boilers, ovens, and thick plumbing pipes.

Applications of Rockwool Insulation

This thermal insulation finds extensive applications in both construction and industrial settings:

- Building Insulation: It can effectively insulate walls, ceilings, floors, pipes, and ducts in buildings.

- Industrial Facility Insulation: It is widely used for insulating boilers, turbines, pipes, tanks, and other industrial equipment.

- Vehicle Insulation: This thermal insulation can be used to insulate engines, exhausts, and vehicle bodies.

- Cold Storage Insulation: Rockwool effectively insulates walls, ceilings, and floors of cold storage facilities.

Insulation Accessories

To complement rockwool insulation installations, various accessories are available:

- Aluminum Foil Cladding: Provides an additional layer of protection and enhances moisture resistance.

- Aluminum and Galvanized Steel Straps: Securely fasten the insulation in place.

- Aluminum, Steel, and Galvanized Steel Posts: Support the insulation and maintain proper spacing.

- Expansion Springs: Allow for thermal expansion and contraction of the insulation.

- Stainless Steel Fasteners: Ensure long-lasting and corrosion-resistant connections.

- Self-Tapping Screws, Washers, Neoprene, Rivets, and Aluminum: Provide secure and versatile mounting options.

- Mastics and Sealant Tapes: Seal joints and gaps to prevent air infiltration and moisture ingress.

Key Considerations

- This thermal insulation is manufactured to standardized specifications and quality control measures.

- It exhibits exceptional resistance to heat, fire, and sound.

- Rockwool is chemically inert and does not cause corrosion on surfaces.

- It is a lightweight, sterile, and contaminant-free material.

Conclusion

Rockwool insulation emerges as a superior choice for insulating buildings and industrial facilities due to its unique properties. Not only does it contribute to energy savings and cost reduction, but it also prioritizes environmental safety and sustainability. With its diverse forms, wide range of applications, and complementary accessories, this rockwool proves to be an indispensable component for achieving thermal comfort, sound control, and energy efficiency.

Leave a Reply